|

AnPing HaiTeng Wire Mesh Technology And Manufacturing Factory

|

Stainless Steel Crimped Wire Mesh

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Material: stainless steel wire, high carbon steel wire, low carbon steel, medium carbon

steel, galvanized iron wire and galvanized wire

Weaving

Stainless Steel Crimped Wire Mesh

Material: stainless steel wire, high carbon steel wire, low carbon steel, medium carbon

steel, galvanized iron wire and galvanized wire

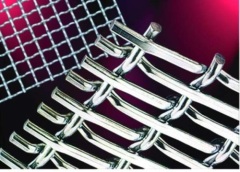

Weaving patterns: pre-crimped or double-crimped Weaving

In the pre-crimping process, wire is first formed (crimped) in precision machines using

rotary dies that precisely define the spacing of the wires and insure that the wires will

lock firmly together at the intersections. The pre-crimped wires are then assembled in

custom designed assembly machines. Pre-crimped wire cloth has very accurate openings and is

woven much tighter than plain weave. It is typically preferred for vibrating screens and

many other applications where sizing and strength is critical.

Property:

* Accuracy of weave

* Regularity

* High stability

* Rigidity

* Corrosion resistance

* Thermal resistance

* Resistance to moisture

* No static loading

* Ease of fabrication

* Extended service life

Usage:

* As wire mesh for mine and stone works, glass factory, coal mine, petroleum, hardware

products, etc.

* Heavy duty crimped wire mesh products are mostly used as screen in mining, coal factory,

construction and other industries.

* Stainless steel crimped wire mesh is mainly used in foodstuff, mine, chemical industry,

pharmacy, metallurgy, machinery, protection, construction, arts and crafts.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Crimped Stainless Wire Mesh

Steel Wire Crimped Mesh

Stainless Steel Wire Mesh

Stainless Crimped Mesh

Decorative Crimped Wire Mesh

Double Crimped Wire Mesh

More>>