|

AnPing HaiTeng Wire Mesh Technology And Manufacturing Factory

|

SUS 302 304L 304 316 316L stainless steel wire mesh

| Price: | 2.1~12.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.SUS 302 304L 304 316 316L stainless steel wire

2.dutch weaving,twill weaving

3.wire dia:0.5-4.0mm

4.aperture:0.0385-6.27mm

SUS 302 304L 304 316 316LStainless Steel Wire Mesh

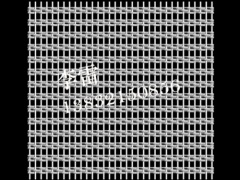

Materials: SUS 302 304L 304 316 316L stainless steel wire. Weavingplain weaving and twill weaving

Type 304 L: with the difference being reduced carbon content; which ensures better weaving and secondary welding characteristics

Type 316: Type 316 has better resistance to corrosion than other chromium-nickel stainless steels where brine, sulfur-bearing water or halogen salts (such as chlorides) are present

A valuable property of T-316 is its high creep strength at elevated temperatures

Wire cloth woven from T-316 has extensive use in chemical processing, especially when better corrosion resistance is required than for regular chromium-nickel types

Type 316 L: with the difference being reduced carbon content, which ensures better weaving and secondary welding characteristics

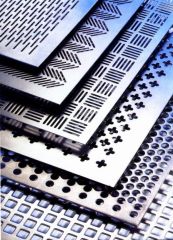

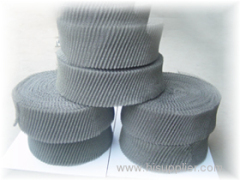

- Weaving patterns involved: plain weave and twill weave.

- Roll width: 1m,1.5m,2m.

- Roll length: 25m, 30m,40m,50m

Specification List of Stainless Steel Wire Mesh | ||

Mesh/Inch | Wire Gauge(SWG) | Aperture in mm |

3mesh x 3mesh | 14 | 6.27 |

4mesh x 4mesh | 16 | 4.27 |

5mesh x 5mesh | 18 | 3.86 |

6mesh x 6mesh | 18 | 3.04 |

8mesh x 8mesh | 20 | 2.26 |

20mesh x 20mesh | 30 | 0.95 |

30mesh x 30mesh | 34 | 0.61 |

50mesh x 50mesh | 38 | 0.36 |

60mesh x 60mesh | 40 | 0.30 |

100mesh x 100mesh | 44 | 0.172 |

120mesh x 120mesh | 44 | 0.13 |

160mesh x 160mesh | 46 | 0.097 |

180mesh x 180mesh | 47 | 0.09 |

200mesh x 200mesh | 47 | 0.077 |

280mesh x 280mesh | 49 | 0.060 |

300mesh x 300mesh | 49 | 0.054 |

350mesh x 350mesh | 49 | 0.042 |

400mesh x 400mesh | 50 | 0.0385 |

Characteristic:Plain weaving or twill weaving. it have the performances of acid-resisting.alkali-resisting heat-resisting and cold-resisting etc.

Application: For acid,alkali environmental conditions sieving and filtering,mud mesh for the oil industry,filters for chemical fiber industry,pickling for the electroplating industry.

Various types of products can be designed and manufactured according to the users'needs, while undertake materials processing.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

304l Stainless Steel Wire

Stainless Steel Wire 304l

316l Stainless Wire Mesh

316l Stainless Steel Wire

Stainless Steel 304

316 Stainless Steel

More>>